As a national high-tech enterprises as well as the first leading brand of China's small and medium-sized gantry machining center, Datan offered a complete new ceramic crucible processing program for VESUVIUS. GLF 1020 gantry machining center exceeded its original equipment from Italy but the cost is 70% less than invested in Italy devices. ……

GS1015 is the first model in small hi-precision, hi-rigidity gantry

machine center. Datan CNC is specialized in customized products

when others are in Gantry machine center. We are clear in what

our clients really want;

we push out the new model which can be nice substitute

to large VMC, quite suitable to the demand of high rigidity.

It improves the efficiency double, gain well market fame.

It is the smallest type of Gantry machine center in market.

machine center. Datan CNC is specialized in customized products

when others are in Gantry machine center. We are clear in what

our clients really want;

we push out the new model which can be nice substitute

to large VMC, quite suitable to the demand of high rigidity.

It improves the efficiency double, gain well market fame.

It is the smallest type of Gantry machine center in market.

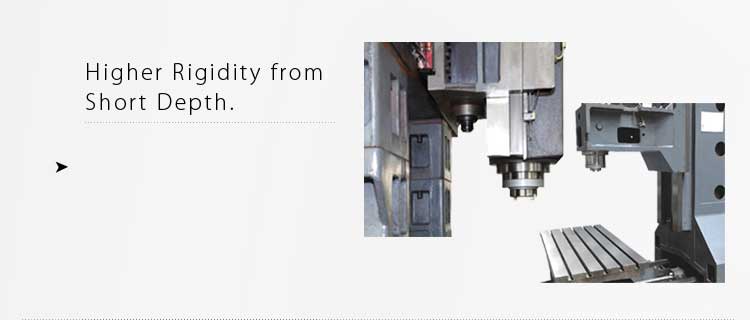

Gantry structure is close structure;

it will gain more rigidity.

it will gain more rigidity.

The gantry structure avoids the

weakness in normal structure, the

depth is 50% less, that means

double in rigidity.

weakness in normal structure, the

depth is 50% less, that means

double in rigidity.

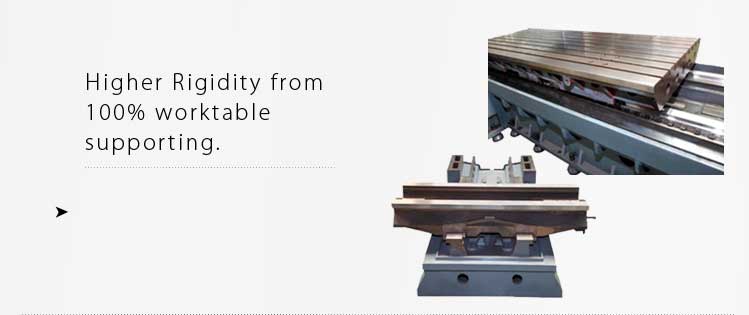

Whole support in worktable, it has more

stability and more weight load.

stability and more weight load.

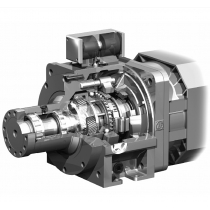

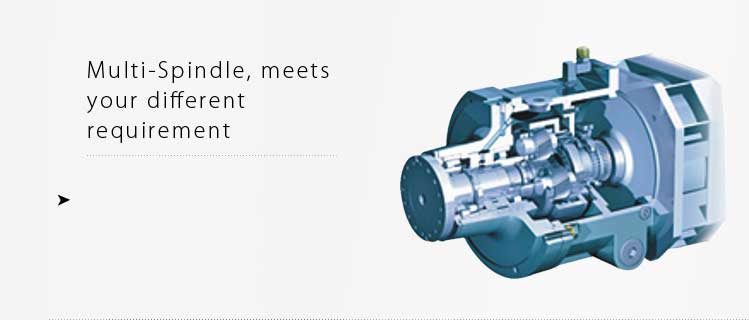

With Germany ZF gear box, speed auto

shifted, this model can meet different

demand if low speed large torque

cutting and high speed either.

shifted, this model can meet different

demand if low speed large torque

cutting and high speed either.

By adopting the large retardation, although lose some speed, it gains the large toque that really need, it is also of high cost efficiency.

It is more stable with N2 balance in Z travel square ram, gains more rigidity. 1:1.5 in worktable ratio makes it more fit to mould type machining.

Tt is more stable with N2 balance in z travel.

Square ram, gains more rigidity.

1:1.5 in worktable ratio, make it more fit to

mould type machining.

Square ram, gains more rigidity.

1:1.5 in worktable ratio, make it more fit to

mould type machining.