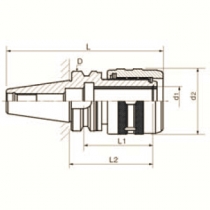

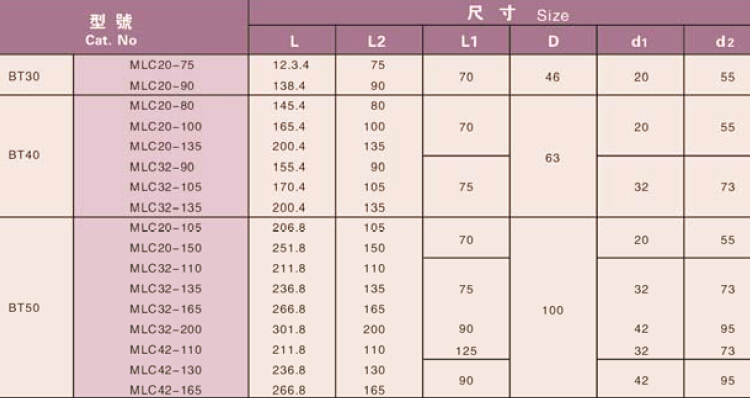

BT-MLC Milling Chuck

Uses the straight collet, precision is high.

1.Shank hole split six slots in order to prevent sliding and increase the clamping force.

2.Two-wire device to make when sliding to rolling friction when the needle cone and minimize shedding.

3.The tool into collet need to exceed the effective clampinglength, so to avoid non-totally gripping,resulting in collet damaged,deformed or de-cutter things from happening.

Department of thicker clamping design,improve the rigidity and prevent vibration.

Clamping strong,beating high precision.