Spindle Reduction Gear Box

In metal cutting industry field, there is the phenomenon that greater torque output is needed with lower sprindle speed.

So,according to the Inverter motor or servo motor torque output characteristic, when the spindle speed is low, the output torque is unable to achieve the maximum torque, at this time, cutting ablity will be low.

We provide two solutions to customers:

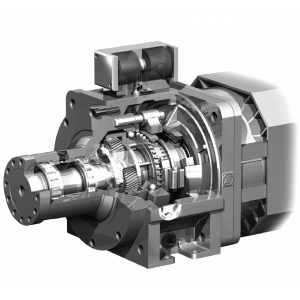

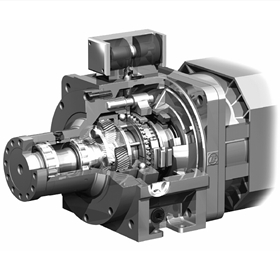

The first: Install ZF brand double speed gear box made in Germany.

The gear box has 1:1 and 1:4 second gear shifting, you can choose 6000r/m high speed cutting or below 1500r/m low speed cutting with a high torque that four times torque than usual in theory.It can make shift without pausing the spindle. Must be cooled with oil cooler.

Although the performance is remarkable, but the price is expensive and in the case of insufficient cooling , it is easy to damage.

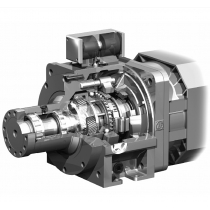

The second project: Datan Brand gear box to increase torque

The gear box can depend on the processing requirements of the customer to choose suitable reduction ratio, such as 1:2. 5, 1:3, 1:4. but it can't shift. In 10000 r/m of the spindle motor cases, the maximum speed limit to 4000r/m by in choosing 1:2. 5 gear box.Therefore, customers should be reasonably choose the right ratio according to the processing needs.

In most cases, the spindle speed under 3500r/m can satisfy the 80% processing requirements. therefore, the customer needn’t just be in pursuit of high speed, but increasing torque will be more realistic. The greatest benefit of this kind of gear box is cheap, Morever, it is not easy to damage.

But If the customer need to use the high and low speed cutting processing in the same time. ZF gear box is the best choice. But if you want to get high torque low spindle speed, selecting the second gear box is better.

Datan brand spindle reduction gear box