Formwork is the semi-finished products of the mould, it is composed of various steel plate with parts, can be said to be the skeleton of a complete set of mold.

Production of Formwork for processing equipment requirement has relatively high ,not only when rough processing with high metal removal rate ,but also when fine finishing with high local precision and surface degree of finish. ……

Strong cutting capacibility

The most excellent response system for counter-balance Z-axis

The most excellent strength in structure

The advanced control system

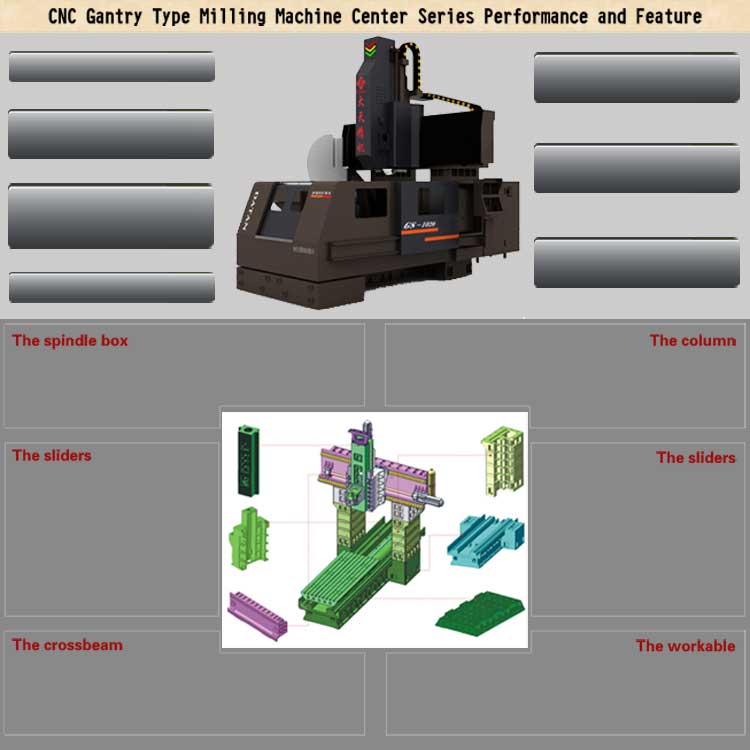

The spindle box is designed on the base of the most applicable rectangular ratio with inside structured by interlayers and arcuated ribs

Special staged propping system with 3 sliders on upper guideway and 3 RG series roller-type sliders makes the travelling range od sliders on the guideway reach 50%-70% of guideway length,deserving a super strength and stability.

The maximized feeding structural system

The most applicable spindle box

The most excellent feeding system

Our columns have adoped box-type structural column and machine weight has increase 25%.

The machine base is made in the form of box-type structure and chip removal slots from one-body formed stout base wall and rib plates have strngthened static rigidity and dynamic accuracy of machine base.

With box-type and staged strctural design, the crossbeam has best moment of inertia for resistance to bending, ensuring the work of machine on Y axis and Z axis with static orecision.

With special closed double-deck sructure, high rigid roller-type slider and RG guideway with best space the bottom,the travelling distance of slider on work table has reachied 25% of table length.

large cnc milling machine