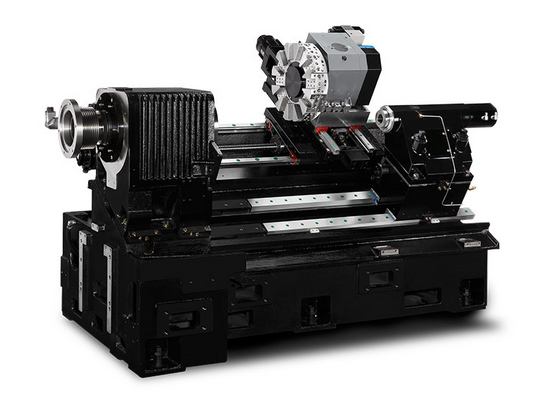

Slant bed lathes commonly referred to CNC turning center, it can load more tools. The horizontal bed Lathes commonly referred to as CNC lathe.

Slant bed CNC lathes and horizontal bed CNC lathe machine:

Horizontal bed CNC lathes, two rails parallel to the plane and the ground plane. Slant bed CNC lathes, two rails and the plane of the ground plane intersect into a bevel angle has 30 °, 45 °, 60 °, 75 ° points. From the machine side, the level of bed CNC lathe bed was a square, slant bed CNC lathe bed right-angled triangle. Obviously, at the same width of the rail, the inclined bed of the X carriage than the level of the bed longer, in practical sense lathe can arrange more CNC tool.

Slant bed CNC lathes and horizontal bed CNC lathe machine cutting rigidity comparison:

Bed cross-sectional area of CNC turning centers of the same size than the level of the bed, which means the resistance to bending and torsional ability. Tool CNC turning center is diagonally above the workpiece is cut down, consistent with the direction of cutting force of gravity and the workpiece, the spindle running relatively smoothly, not easy to cause vibration cutting, horizontal bed CNC lathe cutting tool and the workpiece cutting force generated by gravity into the workpiece 90 °, easy to cause vibration.

CNC turning centers and a horizontal bed CNC lathe machining accuracy comparison:

CNC lathe screw drive are high precision ball screw, lead screw and nut drive gap between the small, but it is not that there is no gap, but as long as there is a gap, when the screw towards one direction and then reverse gear when, inevitably will produce backlash, there is backlash will affect the repeatability of CNC lathes, thus affecting the machining accuracy. Gap slant bed CNC lathe can directly affect the layout of the X-direction ball screw, gravity acts directly on the axial screw, so that backlash when the drive is almost zero. X direction of the horizontal bed CNC lathe without axial screw the influence of gravity, the gap can not be directly eliminated. This is designed to slant bed precision CNC lathes bring inherent advantages.

Slant bed CNC lathes and horizontal bed CNC lathe machine automatic production of comparison:

Machine tool number increases, configure automatic chip conveyor, in fact, are laying the foundation for the automation of production. One person on duty more than one machine, the machine has been the direction of development. Slant bed CNC lathe and then the addition of milling power head, automatic feeder bed or robotic, automatic feeding, a fixture to complete all steps of the chip, automatic cutting, automatic chip removal, it would be very efficient automatic CNC lathes. Horizontal bed CNC lathe structure at a disadvantage in terms of automation. Although CNC turning centers advanced than the level of bed CNC lathes, but the market share is far behind. Advantages level bed CNC lathe production and other easily occupy more than 90% of the CNC lathe market share.